Red Oak Hardwood Floors with a High Gloss Finish Central Mass Hardwood Inc.

The Lombardy collection planks come in random widths of 3", 5" and 7" for versatility and variety in décor. As easy as Sunday morning by the Texas bay, this floor comes complete with 8 coats of ultra-durable finish to express a look that is durable and stands the test of time.

Reclaimed barn oak wood in natural finish with metal base RHome Furniture

Characteristics of Oak Wood. Compared to other wood species, oak is quite dense, making it strong, heavy and durable. Oak is also remarkably water, insect and fungi resistant. The wood from an oak tree is naturally light in colour and features a prominent grain pattern with an uneven texture. It is commonly used for furniture and flooring and.

Heritage Mill Red Oak Unfinished 1/2 in. Thick x 3 in. Wide x Random Length Engineered Hardwoo

Characteristics of Oak Wood. Color: White oak tends to be a light beige through brown, while red oak has pinkish and reddish hues instead. Source: Oak Tree ( Quercus L.) Durability: White Oak 1360 on Janka scale; Red Oak 1290 Janka. Cost: $4.10 to $9.25 per board foot.

Planked Urban Oak 9312 Laminate Sheet, Woodgrains Formica

How to Finish Oak - Lacquers, Oils, and Waxes for Oakwood By Thomas Faessler Posted December 7, 2021 Updated September 9, 2022 Finishing & Sealing When most people think of something that's 600 years old, thoughts of obsolete technology made of cast iron come to mind.

Prefinished Red Oak Natural 3/4"X21/4" Tulip PC Hardwood Floors

Oak (or quercus as it is known in Latin) is a hardwood with some 400 known species. It has always been a popular wood in The UK, but in recent times it is even more widely used in construction and also as internal fixtures in clubs and gyms etc.

Minwax Wood Finish Red Oak The Home Depot Canada

1. Sanding: Start by sanding the oak wood with fine-grit sandpaper to remove any rough spots, imperfections, or previous finishes. Use a sanding block or an electric sander for larger surfaces to achieve a uniform smoothness. 2. Cleaning: After sanding, use a tack cloth or a vacuum cleaner to remove all dust and debris from the surface of the wood.

Click here for White oak flooring with a velvety soft matte oil rubbed finish Natural Wood

It is one of the most durable and flexible woods that they can find. Differences Between Red Oak and White Oak When you hear the term, "natural oak", this is usually referencing white oak, which is also the most popular type of oak wood, and thus, more available for purchase than the red oak counterpart.

Natural Oak 5x12 Sheet Laminate Matte Finish Formica 346

Finishing oak is like finishing two different woods at once. The large, visible pores in the earlywood soak up stain much more aggressively than the relatively smooth latewood does. Click any image to view a larger version. Avoid disasters; make samples first Always, always, always make samples before you begin to apply finish.

PIVOT Front Doors Pivot Modern Entry Doors, Floating Exterior Wood Doors by Quality Window and

1. Traditional Oil-Based Stains: Oil-based stains have long been popular for achieving rich, deep colours on oak wood. These stains penetrate deep into the wood, enhancing its natural beauty while providing excellent durability. They are available in various colours, from light tones to dark shades.

Best Finish for the Most NaturalLooking White Oak Floors Mommy to Max

Step 1: Prepare the work area. Step 2: Clean and sand your oak surface. Step 3: Apply the first coat of wood stain. Step 4: Wait for the stain to dry. Step 5: Apply the second stain layer. Step 6: Wait for it to dry, and recoat if necessary. Step 7: Apply a finish coat. How many stain coats are necessary? How to stain oak wood lighter

Oak Wood Stain Colors

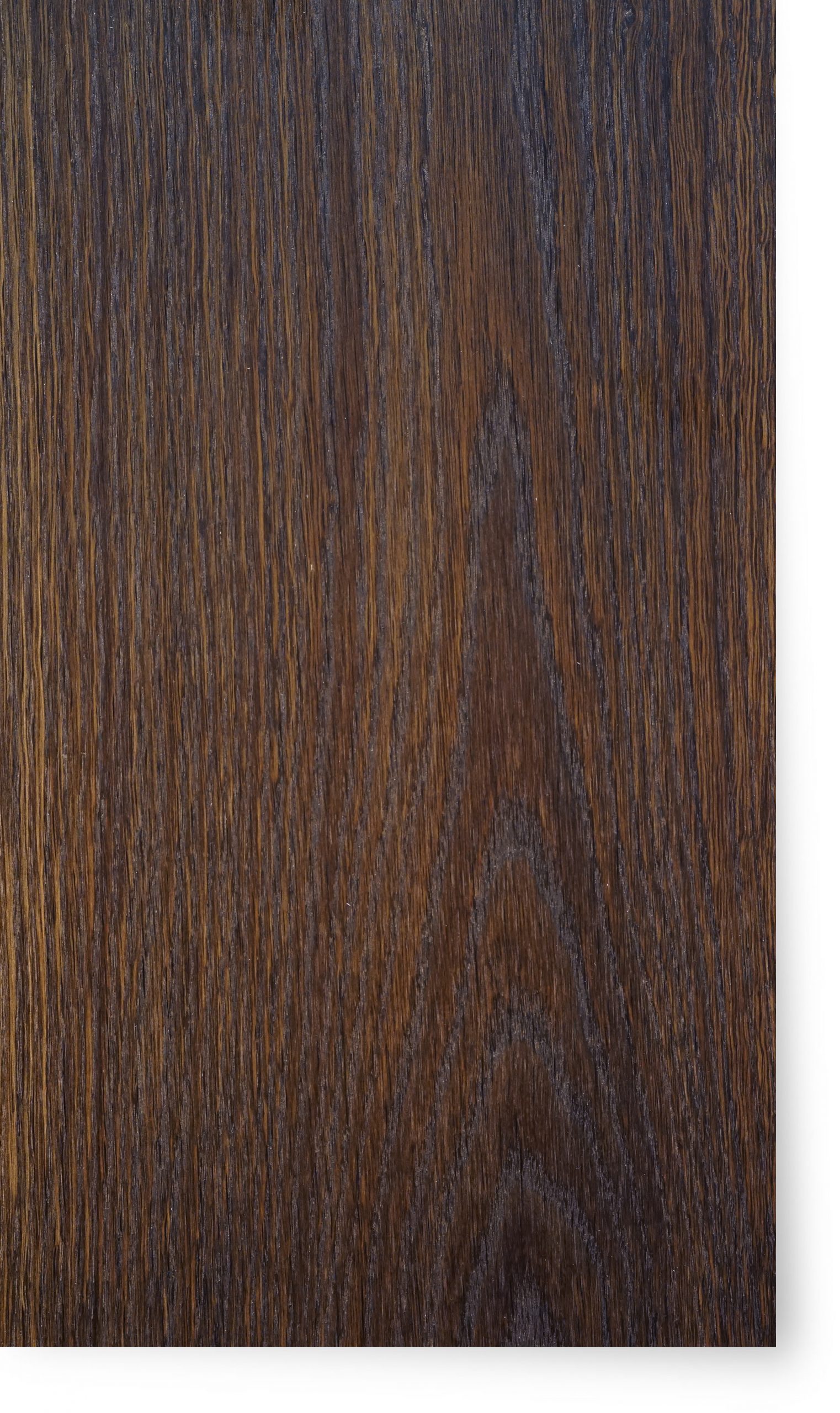

1 6 Finishing oak with finesse The following slides show the look of red oak with various finishes. Because of oak's cellular structure, the pigments in oil-based stains collect more in the wood's open grain areas, while the smoother, denser, surrounding areas retain less. This can result in strong light/dark contrasts.

Black Oak Collection Pure

Danish oil: Smooth and easy. When it comes to bringing out the natural beauty of a highly figured piece of wood, such as quilted maple or quartersawn oak, nothing beats a hand-rubbed Danish-oil finish. Typically a Danish oil consists of a mixture of tung oil and varnish. It penetrates into the wood, unlike a film finish, which sits on the surface.

Natural White Oak Floors with Oil Based Finish Central Mass Hardwood Inc.

Oak treatment and finish options There are more than a few oak treatment finishing options that will work well for exterior uses. Below we will mention and explore each option as well as the environment in which they work best. Before deciding on a finishing treatment, there are some factors to consider:

Murphy Bed Oak Finishes Wilding Wallbeds

Oak is one of the most revered and appreciated species of stock used in fine woodworking projects. It is hard, strong, and when finished properly, absolutely beautiful. Oak can also be a royal pain to work with.

Thomasville Finishes Natural on Oak

Minwax Simply White on Oak Wood; This product works best for those preferring soft colors. Also, it can soften white and red Oak without masking their lovely natural grain. Minwax Simply White is a translucent finish. Thus, it partially conceals the lumber's undertone. Minwax Dark Walnut on Oak Wood; This Oak wood finish makes the wood darker.

Factory Finish Guide Five Lakes Manufacturing

updated March 24, 2023 Danish Oil on Oak Wood: We Tested it Danish oil is a type of finish often used on wood. It's a mixture of tung oil and varnish that seeps into the wood and gives it a protective layer. You can find its applications in furniture and other woodworking projects. Danish oil is an excellent finish to use on oak wood.